EZC Working Principle

Revolutionary Global Offset Printing Solution

Fast, accurate, stable, and cost-effective. The extraordinary future of smart printing

For a long time, the color control of conventional offset printing has relied heavily on the experience of the printing press operator. Relies on the observation of the human eye, the ink key value is repeatedly adjusted color by color one by one, or a more advanced closed-loop ink control system is used to repeatedly correct the ink key value according to the scanning results; operation process is cumbersome, printing efficiency is low, heavily dependent on manual experience and printing quality is still unstable.

Whether it is manual or closed-loop ink control system, they are doing one thing: "repeated error correction".

The printing industry is in urgent need of a solution that can improve print quality and stability from the ink delivery source. The CRON EZC Intelligent Digital Ink System has emerged to address this demand.

µL-level high-precision digital ink pump + iColor intelligent color control system = one-click ink discharge, extraordinary color starts at the source!

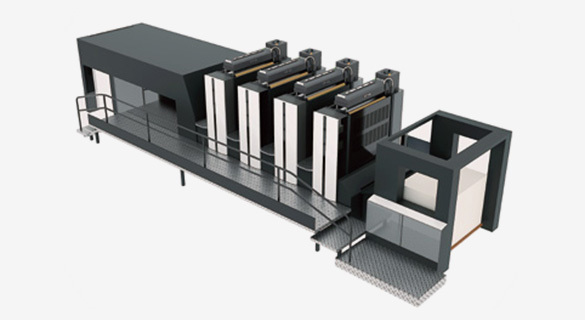

EZC working principle

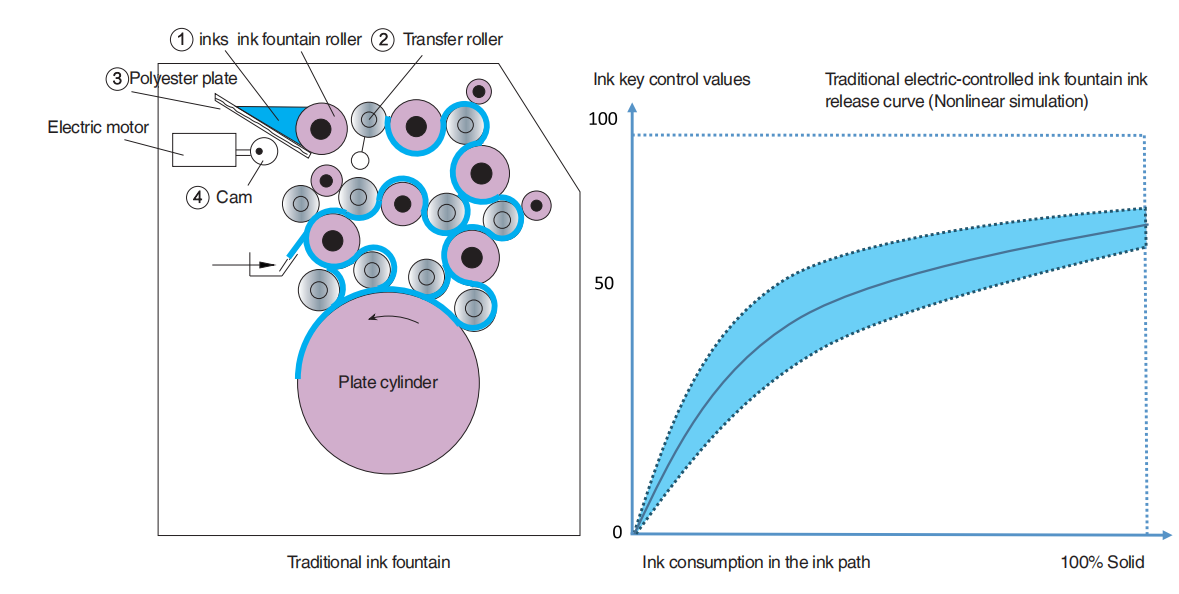

Comparison of mechanical structure and working methods of traditional ink fountain and EZC digital simulation.

The color of the printed matter is mainly determined by the amount of ink, and the amount of printing ink is determined by the performance of the ink fountain discharge system. The performance of the ink discharge system needs to meet: the stability of the ink transfer, the uniformity of the ink transfer and the accuracy of the ink amount transfer.

EZC digital inking system

EZC replaces the ink keys on the traditional printing press with a high-precision micro-upgrade metering ink pump to achieve continuous ink supply by sheet, solving the long-standing issue of unstable, non-uniform, and imprecise ink release. EZC calculates the ink volume required by the printing image in each ink channel using a patented algorithm, and drives the EZC digital inking control unit to directly and accurately dispense ink to the corresponding ink roller of the printing press. This replaces the traditional ink transfer roller, ensuring stable, uniform, and precise control of the required ink amount, resulting in highquality prints with accurate and consistent colors.

EZC digital inking system

EZC replaces the ink keys on the traditional printing press with a high-precision micro-upgrade metering ink pump to achieve continuous ink supply by sheet, solving the long-standing issue of unstable, non-uniform, and imprecise ink release. EZC calculates the ink volume required by the printing image in each ink channel using a patented algorithm, and drives the EZC digital inking control unit to directly and accurately dispense ink to the corresponding ink roller of the printing press. This replaces the traditional ink transfer roller, ensuring stable, uniform, and precise control of the required ink amount, resulting in highquality prints with accurate and consistent colors.

EZC working principle

Traditional ink fountain

The traditional ink fountain is difficult to evaluate which parameter adjustment can achieve the desired ink supply due to the combined control of the ink key opening and the ink fountain roller angle. Additionally, the wear of the steel plate or polyester plate at the ink delivery outlet prevents accurate zero positioning, resulting in non-linear ink supply from the ink supply device, which affects the uniformity and consistency of print colors.

Unavoidable technical flaws of traditional ink ducts

1、Ink: Expose to air makes it susceptible to ambient temperature and humidity, and it can also form ink skinning.

2、Ink transfer roller: angle of the ink transfer roller and the printing speed together affects the accuracy of ink delivery.

3、Polyester foil: easy to wear off and a ects the accuracy of zero positioning.

4、Cam Wheel: Due to mechanical precision limitations, achieving a level zero position is challenging.