Technical advantages

EZC software technology: iColor intelligent color control system

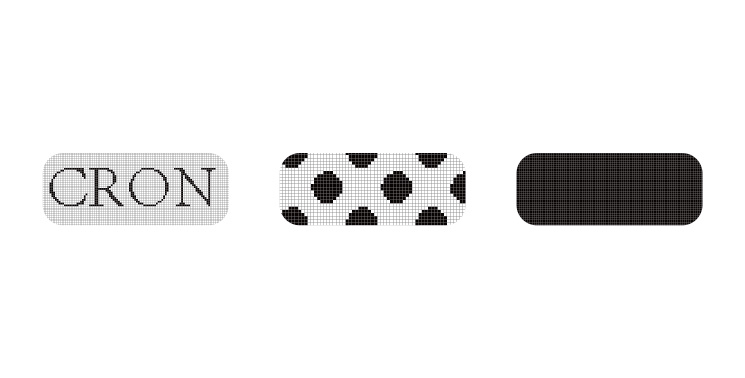

1. Accurate ink volume algorithm

From fuzzy area to precise volume

Traditional CIP3 ink presetting relies on basic PPF to gather statistical ink coverage data for printing images. In contrast, the EZC ink volume algorithm incorporates offset printing's ink transfer characteristics, allowing for precise adjustments in image, halftone, and text areas. By integrating EZC's standard ink layer thickness, it accurately calculates the ink volume in the ink duct.

2. Expert database

Comprehensive ꞏ Scientific ꞏ Accurate, different standards are equally excellent

iColor leverages expert databases to automatically calculate the optimal ink volume required for each ink duct based on different printing images, considering ink, paper, printing plate, blanket, environment, and color standards. With real-time ink release by digital ink pumps, there is no need for manual color calibration. Printing starts immediately upon startup, achieving colors that meet ISO12647 international color standards or customer-specific requirements.

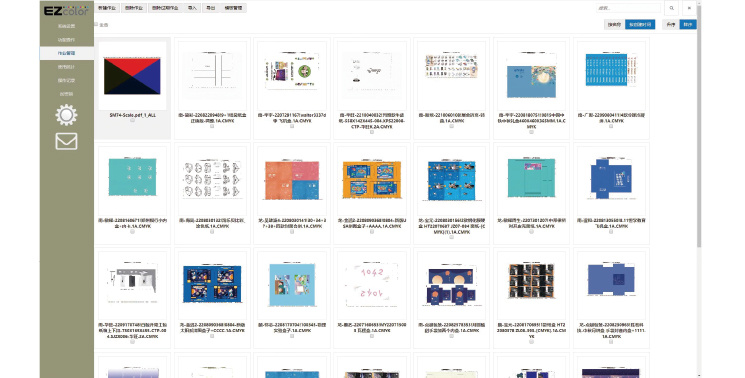

3. Real-time job data collection and management

Open integration with ERP and MES systems

iColor enables real-time data collection and management for operations, precisely tracking consumption of paper, ink, time, and electricity per order. It delivers accurate cost, efficiency, and profit analysis data to customers, with seamless integration into their ERP and MES systems.

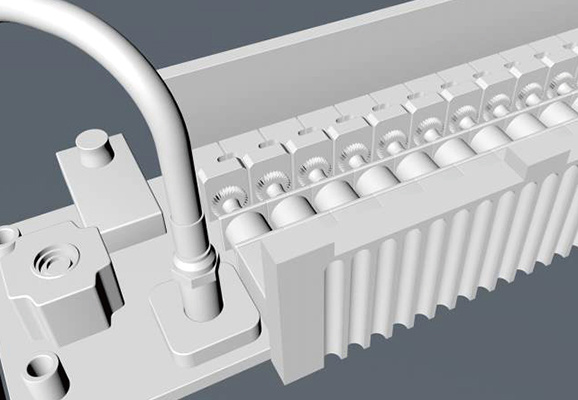

EZC Hardware Technology: High-Precision Digital Ink Pump

μ-Level Intelligent Precision Ink Release

The EZC digital ink pump enables intelligent and precise ink release according to software-calculated ink volumes. Synchronized with the printing press speed, it delivers accurate and continuous ink supply per sheet, achieving ink supply precision at the μL level with an error margin of less than one thousandth.

EZC digital ink pump utilizes an innovative ceramic design, providing superior durability and sealing to prevent ink from drying or crusting, whether in operation or at rest.

EZC Software Technology

iColor intelligent color control system

Ink Accurate Algorithm

From fuzzy area to precise volume

Traditional CIP3 ink preset is based on simple PPF, statistical printing image ink channel area information. The EZC ink volume algorithm combined with offset printing ink transfer characteristics, respectively, the image field, dot, text to do more accurate area correction, in the combination of EZC standard ink layer thickness, and finally get the ink volume of the ink channel.

Expert database

Comprehensive, scientific and accurate, different standards are equally excellent.

Relying on the expert database, iColor automatically calculates the optimal ink volume required for each ink channel according to different printing images, integrating ink, paper, printing plate, blanket, environment and printing color standards. The digital ink pump dynamically releases ink in real time without manual intervention to calibrate the color. The printing color can reach the ISO12647 international color standard or reach the factory standard set by the customer himself.

Digital Correction Technology

From fuzzy area to precise volume

The Orthodontic Center was established in 2011 and an independent orthodontic hospital was established in 2018. It is a digital aesthetic orthodontic center focusing on clinical medical treatment, teaching and scientific research of orthodontics.

EZC Hardware Technology

High precision digital ink pump

μL-level intelligent precise ink discharge

EZC digital ink pump can intelligently and accurately discharge ink according to the ink amount calculated by the software algorithm, realize synchronization with the speed of the printing press, and supply accurately and continuously according to sheets. The ink supply accuracy can reach μL level with an error of less than 1. EZC digital ink pump uses a subversion of the traditional ceramic ink pump, with better wear resistance and sealing, to ensure that the pump ink regardless of the working state or non-working state will not dry crust.