Customer Application

EZC does not need manual intervention or scanning closed-loop correction. It is specially designed to provide services for customers who are committed to pursuing high-quality printing, standardized printing and green environmental protection printing. Customers need to have standardized printing intention, the printing machine has good running state, pursues business quality and has broad business development space.

Application advantages: Intelligent printing with extraordinary colors

Comprehensive, scientific, precise, and equally outstanding with different standards

03

Steady

Ink balance is stable, printing color is stable, batch turnover is stable, production printing is stable.

04

Province

Save the cost of printing enterprises, save time and effort, non-destructive installation.

EZC Application Fields

Labels, Collation, Commercial, Packaging, Books and Magazines

EZC requires no manual intervention and no scanning closed-loop correction. It is specially designed to provide services for customers who are committed to pursuing high-quality printing, standardized printing, and green printing. It serves customers who are eager to standardize their productions, maintain their printing machines in good operating state, and pursue high business quality and broad business expansion.

Achieving color standards now only requires about 10 meters of make-ready paper. This reduces the waste of consumables and time costs associated with repetitive color adjustments or high reject rates. This significantly improves the efficiency of job changeovers. The enhanced print quality leads to increased profitability per order, thus expanding the profit margin for the printing company.

View DetailsMeeting the stringent quality requirements of customers, the EZC system has nearly two-thirds reduction in commissioning time and waste of consumables, greatly reducing the operational intensity for machine operators and production management pressure. This results in improved speed and quality of print delivery, further expanding the profit margin.

View DetailsThe popularity of the Internet has created a fertile ground for fast printing. With the economic development and the transformation and upgrading of consumption, the fast printing has the characteristics of low price and efficient delivery, which can no longer fully meet the needs of customers. The rate of increasing customer complaints seems endless. After the installation of EZC system, a one click ink release achieves the international standard, and the efficiency of plate changing is further improved. Under the rhythm of efficient delivery, the quality of printed products is significantly improved. This greatly enhances customer satisfaction, simplifies production management, and boosts both order volume and throughput.

View DetailsAs the external "identity symbol" of commodities, packaging is increasingly valued by brand owners. Therefore, packaging and printing have higher requirements for color accuracy, consistency and expressiveness. Challenges for packaging printing include maintaining color consistency and large-area color uniformity during long-run printing and batch reprinting. After installing the EZC system, the ΔE value, which represents the color difference between packaging and printing, stabilizes within 2.0.

View DetailsCMYK+OGV 7-color high- delity printing, with its richer color space and enhanced expressiveness, is a technique many high-end printers aspire to master. However, it has extremely high requirements for color control and stability. With the support of professional software, the density of 7-colors after conversion by ICC color gamut is required to be fixed. If the color fluctuation range is large during printing, the printing effect and quality will still not reach the ideal state. EZC solves the fundamental problems of inaccurate ink release and unstable color control in traditional ink fountains, ensuring the printed product has a consistently high quality. The wide color gamut performance space helps 7-color high-fidelity printing to continuously output high-quality prints.

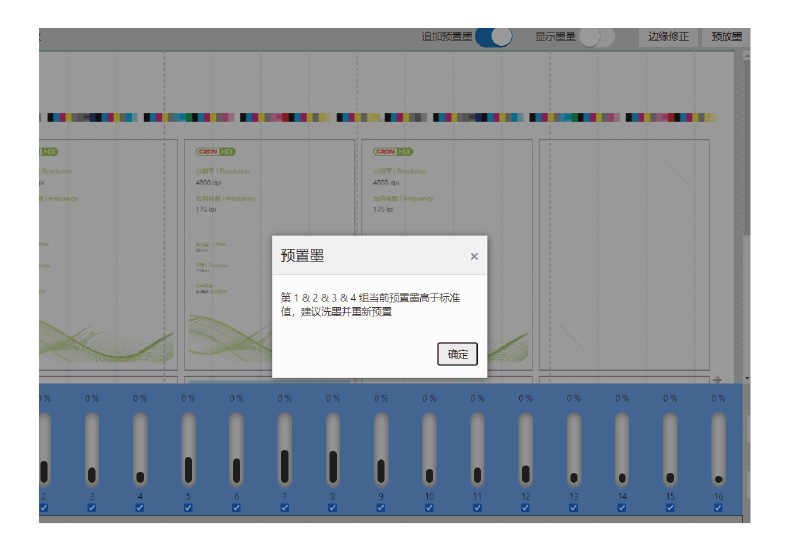

View DetailsLarge ink volume, small ink volume job printing

EZC system creatively uses “auto frequency switching technique” to discharge ink. When in printing jobs with high ink levels, a continuous ink discharge mode is used to ensure that the ink is transferred to the printing press both continuously and evenly. This prevents ink from stacking on the ink transfer roller, which can occur when a large ink volume is being handled by the printing press. For jobs with low ink levels, effective dynamic compensation is used to keep the ink in the non-image portion of the ink roller at an optimal state.

View Details